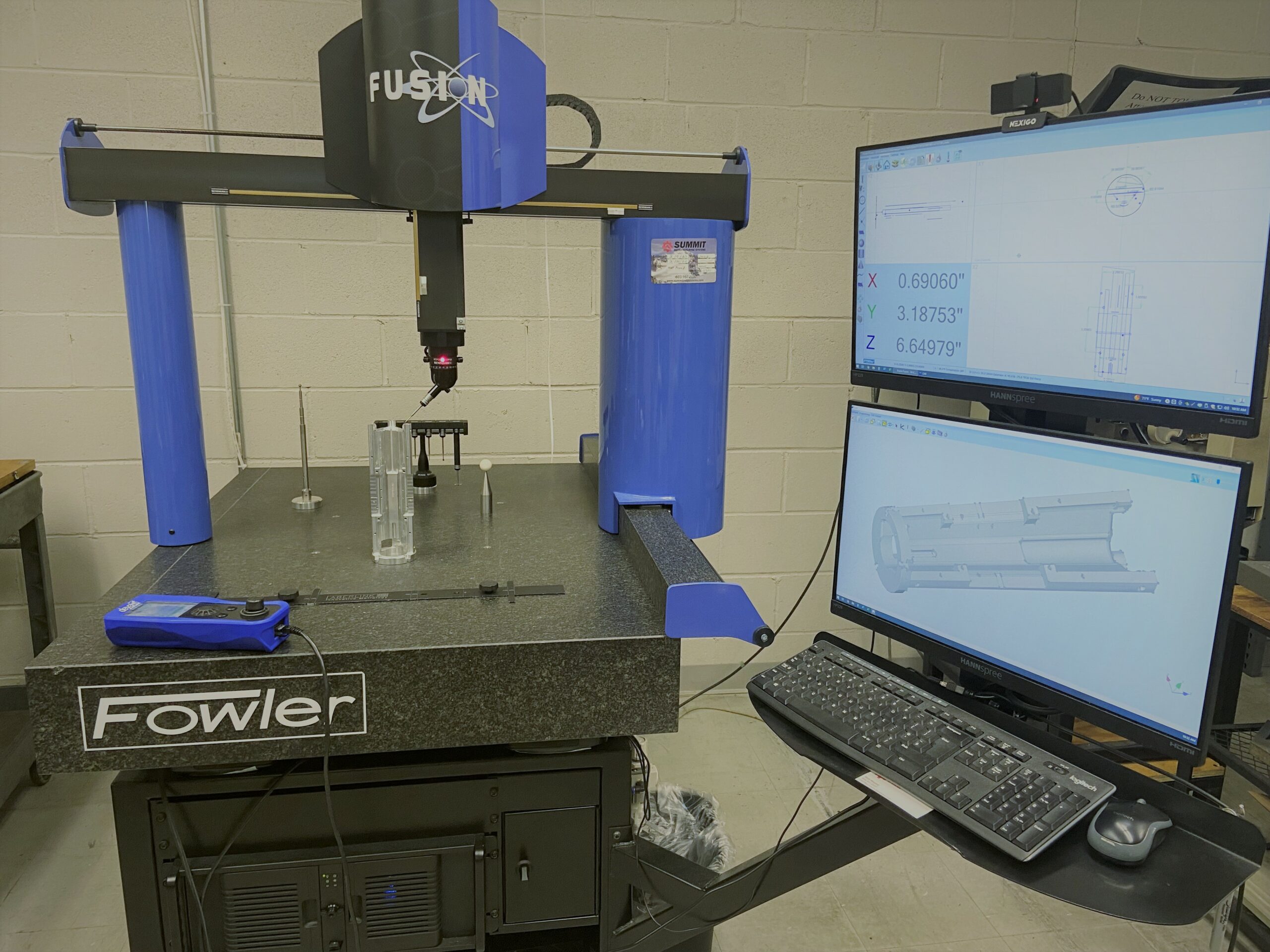

Coordinate Measuring Machine – measures down to .00001″

Quality Control

Our climate controlled quality lab utilizes a wide range of modern equipment to assure compliance to customer blueprints and specifications. We achieve this through our experienced and professional inspection staff utilizing our coordinate measuring machine, optical comparator, Tesa-Hite and numerous other calibrated gauges and inspection equipment.

- Full calibration system traceable to NIST

- Regularly customer and FAA audited

- AS9100D & ISO 9001:2015 certified QMS system

Inspection Equipment

- Fowler Mark 2 HS Programmable/Automated CMM

- Nikon Optical Comparator 5x-50x

- Accupro Hardness Tester

- Granite Surface Plate 58″ x 85″

- Granite Surface Plate 24″x36″

- Granite Surface Plate 30″x48″

- Fowler Trimos V4 Elec. Height Gage 30″ Travel

- B&S Tesa-Hite Elec. Height Gage 18″ Travel

- Starrett 24″ Cadillac Height Gage

In addition to the inspection equipment listed, we possess a full assortment of micrometers, indicators, bore gages, pins, blocks, ring gauges, thread gauges and other inspection tools essential to ensure the highest level of accuracy for all of our machined parts and assemblies. All of which are regularly calibrated per our ISO standards and traceable to NIST.

Contact Us • info@whalleyprecision.com • 413-569-4600